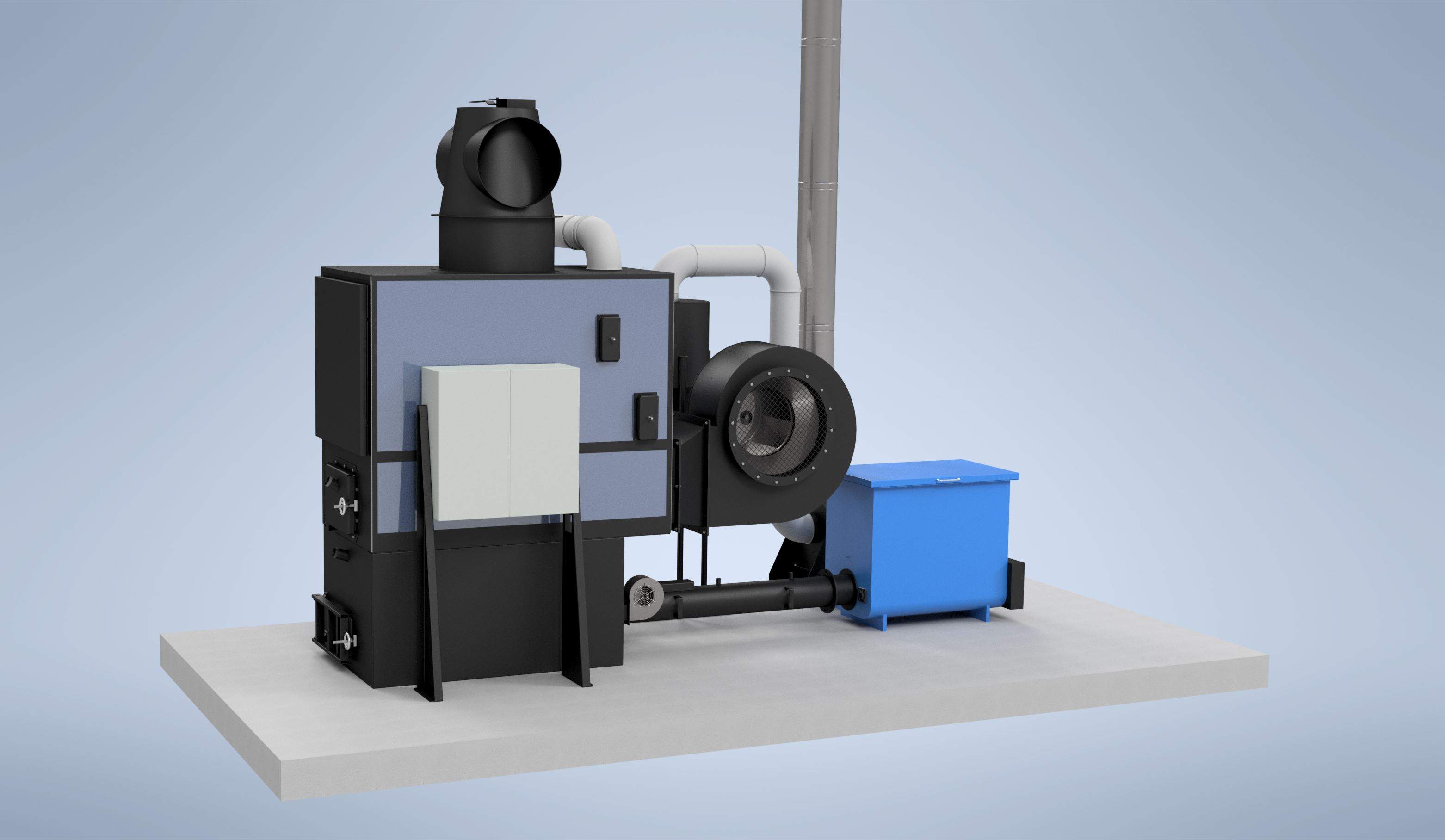

The Ranheat WA150 is the perfect machine for workshops to start automating the disposal of their wood waste. Capable of burning both virgin wood and man-made board in a variety of forms including chipboard, MDF, and OSB. Burning dust, chips and shavings. It available in with a Bagloader feeding system and fully automatic feeding system.

The Ranheat WA150 has the capacity to dispose of 0.5-6tons of wood waste a week. It has lots of different configurations and methods of loading. Every business is different, take a look below and find your perfect configuration.

| Comfortable Disposal Per Week | Configuration |

|---|---|

| 500kg-1000kg | WA 150 BagLoader |

| 800kg-2500kg | WA 150 with BB-2 |

| 1000kg-4000kg | WA 150 with B10 Silo |

| 2000kg-6000kg | WA 150 with C28 Silo |

| System | Loading Options |

|---|---|

| WA 150 Bagloader | Dust in the BagLoader offcuts in the front |

| WA 150 with BB-2 | Fed Via one previously Bagged Dust Extraction Unit. |

| WA 150 B10 Silo | Centralised Dust Extraction Unit or Conveying System |

| WA 150 with C28 Silo | Centralised Dust Extraction Unit or Conveying System |

Bin the Briquette machine. The WA 150 BagLoader allows for dust to be loaded via the BagLoader, while offcuts can be fed through the front. This method offers the lowest capital cost for loading and provides scalability for future expansion.

Pros:

Cons:

The WA 150 HoggerLoader is ideal for clients whose waste primarily consists of offcuts, such as sheds, pallets, and structural timber. This system also has the capability to burn dust when fed via dust bags.

Pros:

Cons:

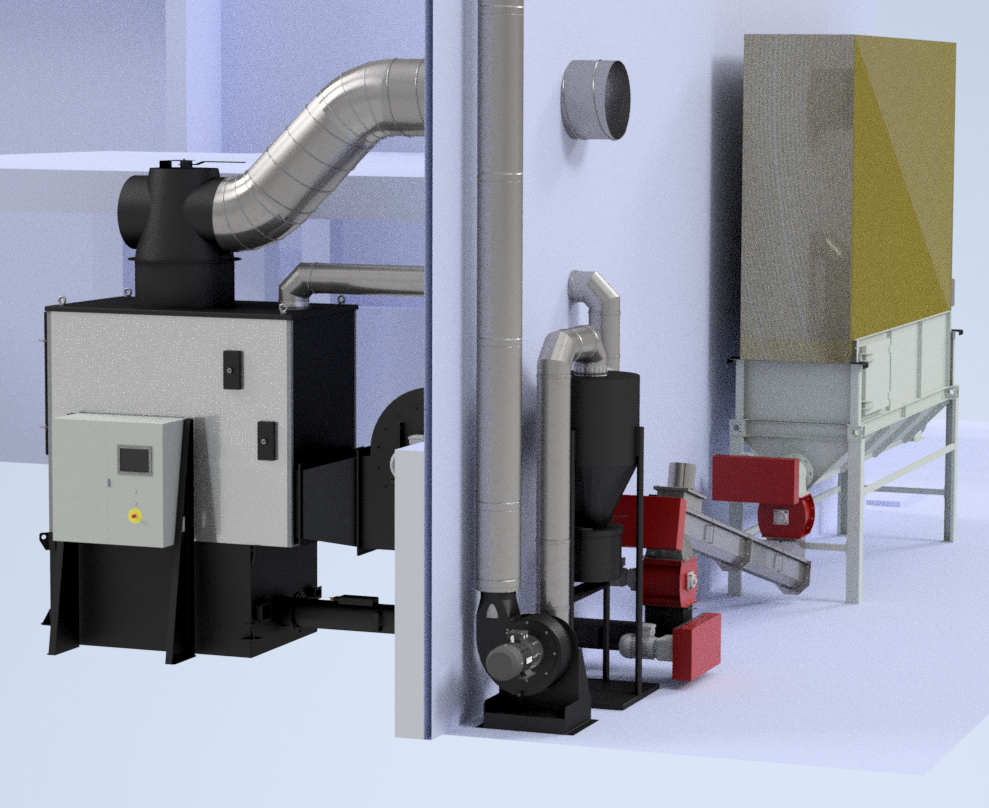

The BB-2 Bunker is the smallest silo option, designed for maximum flexibility. Growing woodworking businesses that are scaling up often have one or multiple bag-emptied dust extraction units. The BB-2 is intended to be retrofitted into factories with these units. With a small amount of buffered storage, a WA 150 with a BB-2 silo can fit well in a tight footprint and has a modest capital cost. The WA-150 can also be upgraded with extra silo storage later, with the BB-2 being part-exchanged. BB-2 silo is also available with a canvas top for customer that require a manual fill.

Pros:

Cons:

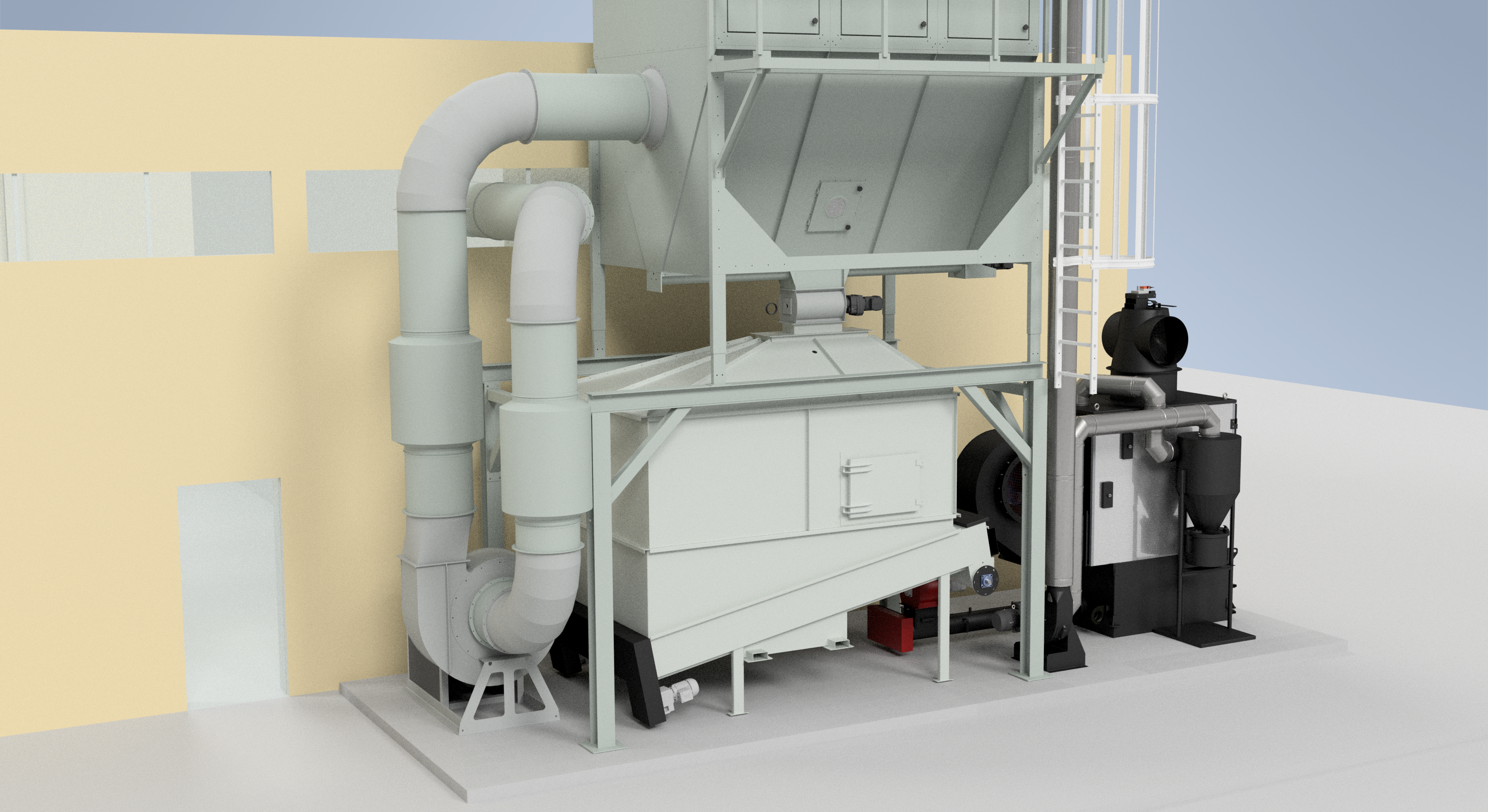

The B10 Bunker Silo efficiently manages wood waste. With a capacity of 10m3 and the ability to store over 3 tons, it suits various business sizes. It features a low entry point fitting under most centralised Dust Extraction filters. Great for fitting down the side of existing Factories.

Pros

Cons

This configuration builds the transfer screw into the outfeeder. Perfect for tight spaces. Also available in a B6 Bunker Silo for a shorter configuration.

Pros

Cons

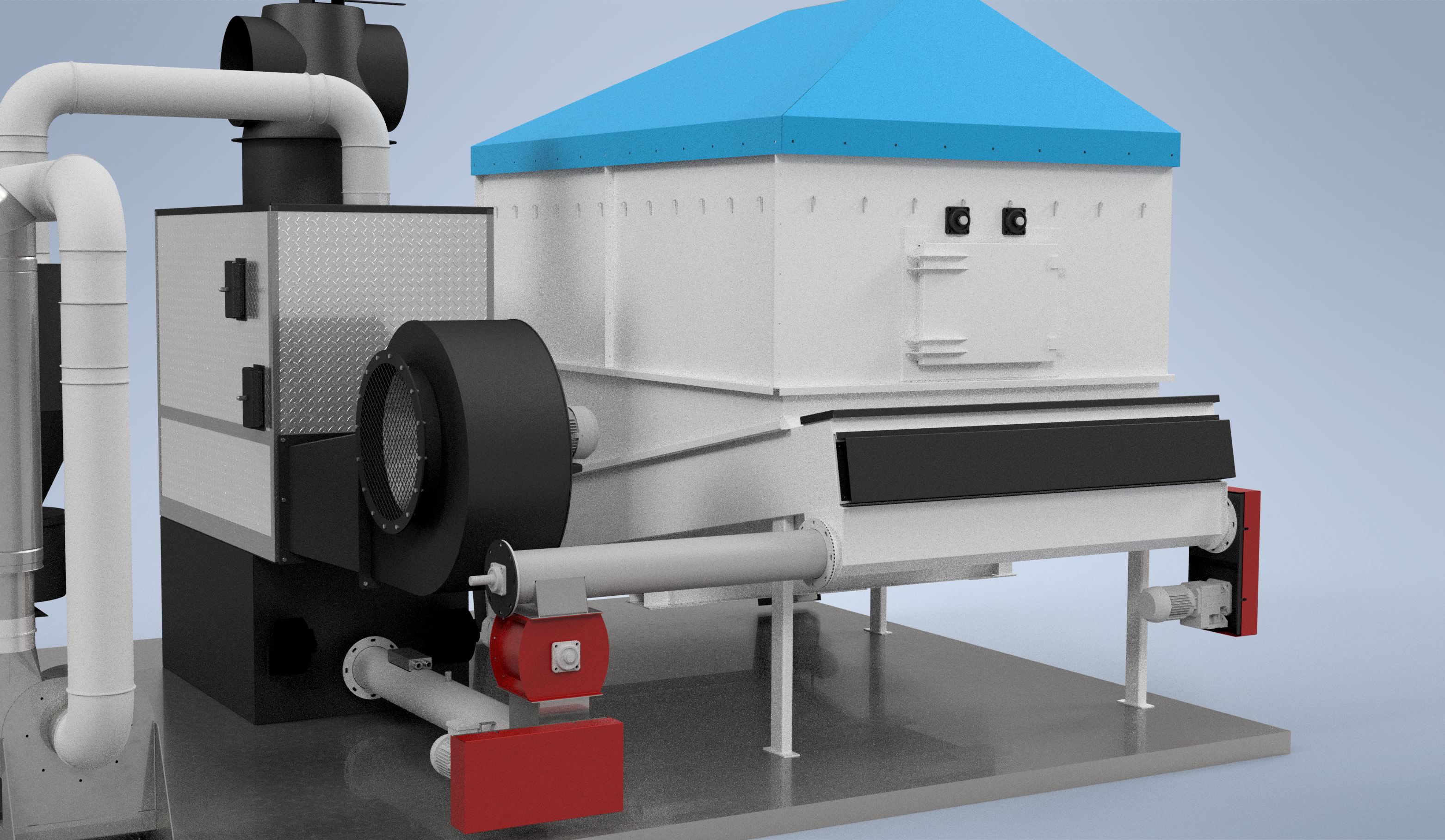

Conical bottomed silos are the most space efficient storage method for storing industrial wood waste. They pack lots of storage volume in a tight footprint. Conveying material into these silos can be as simple as mounting a dust extraction system on top, with or without rotary valve. Or for dust extraction systems with large footprint and conveying system can be used. This can be either pneumatic, screw/auger based or drag conveyor

Pro

Cons

Explore the Ranheat WA 150 Industrial Biomass Burner in detail. Click on each part of the cutaway diagram to learn how our 5-pass heat exchanger, automatic stoker feed, and high-capacity combustion chamber work together. Discover why Ranheat is the leader in wood waste heating for woodworking factories and biomass systems.

Click the Spots on the diagram to find out more…

The winter/summer diverter optimises your industrial biomass burner for year-round use. Redirect warm air to your workshop in winter or vent it safely outside in summer. Fully automatic diverter options are available for hands-free operation—saving energy and maximising comfort in any woodworking factory or biomass system.

Our 5-pass tubular heat exchanger is engineered for maximum energy extraction. With efficiency rates up to 95%, the WA 150 Industrial Wood Burner captures more heat from wood waste, lowering your fuel costs. Compact, powerful, and easy to maintain—it’s a critical advantage for any modern biomass heating system.

Our horseshoe design allows for significant surface area increase resulting in a more efective heat transfer. Lined with Fire Bricks to lengthen the life of the of the system.

Ranheat’s modular design ethos allows for complete replacement of parts resulting in lower maintenance costs. Our modular design also facilitates complete upgradability as and when required.

The stoker will automatically bring wood waste from the bag loader (or other feed systems) automatically into the fire chamber at a consistent and steay pace.

Ditch the labour, keep the heat. Automate your waste with the WA 150.

Don’t throw money in the skip. Calculate the value of your wood waste.

PDFs for the example layouts for all the configurations of the WA 150.

The Ranheat WA 150 is designed to burn a wide range of wood waste materials, making it a versatile heating solution for woodworking businesses. It can efficiently burn fine wood dust, sawdust, wood shavings, and small offcuts, which are common by-products of joinery workshops, furniture manufacturing, and sawmills. The system is also capable of handling processed board materials, such as MDF, chipboard, and plywood, provided they are burned in accordance with emissions regulations and necessary permits. For operations using dust extraction systems, the WA 150 can integrate seamlessly, ensuring an automatic and consistent fuel supply. Whether used in a manual loading configuration or with an automated BagLoader system, the WA 150 allows businesses to convert wood waste into efficient, cost-effective heating, reducing disposal costs and maximizing sustainability.

Choosing between a Ranheat Warm Air System and a Ranheat Boiler System depends on the heating requirements, fuel handling preferences, and operational needs of the business.

Both systems provide cost-effective, sustainable heating solutions, ensuring businesses can maximize energy efficiency while reducing waste disposal costs.

| Power | Maximum Disposal |

|---|---|

| 150kW | 6 tons/week |

| 300kW | 12 tons/week |

| 1100kW | 42 tons/week |

Take control of your wood waste with a Ranheat WA 150 Industrial Biomass Heater. Whether you’re upgrading from a briquette system or automating your waste disposal for the first time, our modular, configurable units are designed for UK woodworking workshops and factories. Burn dust, offcuts, chipboard and more—all with up to 95% heat efficiency.

Ranheat systems let you streamline your workshop, reduce fossil fuel bills, and meet emissions compliance effortlessly. From BagLoaders to fully automated silos, there’s a biomass system for every scale.

See how businesses across the UK and Ireland are transforming wood waste into clean, cost-effective heat. From staircase manufacturers to timber yards, Ranheat systems have helped clients cut fossil fuel bills, meet emissions standards, and turn offcuts into opportunity. Discover which configuration worked for them—and what could work for you.