Monitor and troubleshoot your Ranheat biomass boiler and silo remotely

You use your Ranheat biomass burner/boiler to heat your factory and burn off waste material stored in your silo. You need to keep an eye on how things are running, so that business-critical processes are not affected: without fail, your paint line must run, your kilns must burn, and your waste wood chips must be disposed of. All of these are handled by your Ranheat system which will run unattended. But what if could need to check while away from the factory, or from the comfort of your office on a cold winter morning? Or would you like instant support from our team of engineers to troubleshoot the system if a problem appears?

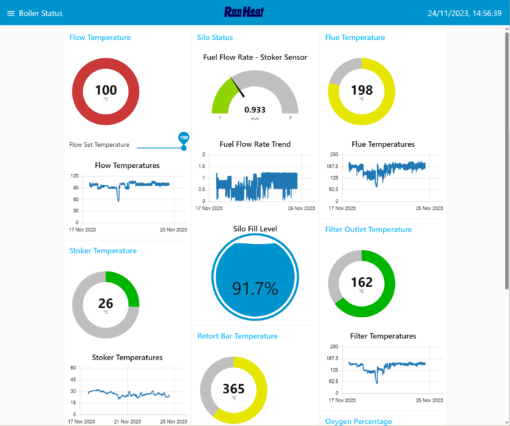

RanheatIO is a comprehensive remote control and monitoring solution for your Ranheat biomass burner system. If you have ever wanted to monitor your RHI output, start/stop you boiler system without travelling down to the yard, monitor your factory temperatures or silo fill levels, from anywhere in the world, then this is what you need!

Custom industrial automation controls are also an option.

The RanheatIO system is designed for the latest generation Mitsubishi FX5U PLCs, installed as standard with all Ranheat burner control cabinets since 2018. Thanks to its modular nature and our in-house engineering expertise, the system is also retro-compatible with IMO PLCs and legacy FX3 PLCs. We use state-of-the-art network gateways (BB-400, MOXA) and Mitsubishi GOT HMI screens to provide secure remote access via OpenVPN to the following controls. If you recently upgraded from a legacy E1000-series keypad, you may already have most of the necessary hardware already available in your control cabinet.

You can remotely control your boiler system and monitor key data from the comfort of your office: temperature trends, temperature samples from multiple system parts, startup, shutdown, etc. Every control available on your control panel’s built-in HMI is made available via a VNC “remote desktop”, accessible from any internet connected device via any standard VNC client software.

Requires installation of compatible HMI, e.g. Mitsubishi GOT GT2107-WTSD

Need a quick overview of your boiler temperature, silo levels or a remote switch for that automated window? Want to show your climate contributions on a dashboard? Or your mobile device simply does not scale well with VNC “remote desktop”? An alternative private webpage is also provided, from which the temperature trends, silo fill levels, fuel feed rates, etc. are also displayed, in a user-friendly manner. All you need is a network connection and a web browser!

Reliable operation of your burner system is key to the smooth running of your factory during production. With RanheatIO, you can view your boiler’s event logs remotely. And receive email and SMS alerts. In case of any emergency shutdowns or issues with your primary means of sawdust disposal, you will be the first to know, and can raise a support ticket or call an engineer to quickly return to full production and heating capabilities. RanheatIO also enables remote support capabilities with Ranheat Engineering’s team of technicians. Issues can be remotely diagnosed and often remotely resolved on the same day, without needing an engineer callout. Advanced operating settings can also be adjusted on request to fine tune how your boiler system runs.

All new Ranheat burner installations, typically from 2018 onwards, that opt for an FX5U PLC come with 1 year of RanheatIO remote access included. Upgraded installations also come with 1 year RanheatIO remote access included.

Renewal is included in our boiler service contracts, or available standalone for a competitively priced subscription. The subscription pricing model allows us to maintain the remote access infrastructure and continuously develop improvements to the various digital interfaces provided.

Contact us for a quote or further information at:

+44 (0) 1604 750005

62 St James Mill Rd, Northampton NN5 5JP UK

Registered in England No: 2644558. Vat No: GB 576 7078 94