By Alexander Franklin – Director, Ranheat Engineering Ltd

Not all industrial biomass boilers are built alike. While some systems are optimised to hit the lowest possible capital cost, Ranheat builds boilers like industrial machines—with the strength, tolerance, and serviceability required to last decades.

Think of it like comparing a consumer petrol car to a diesel-powered workhorse. One is made for price. The other is made to work, day in, day out, for years.

Here’s what makes Ranheat’s boiler design different—and why those decisions matter in the long run.

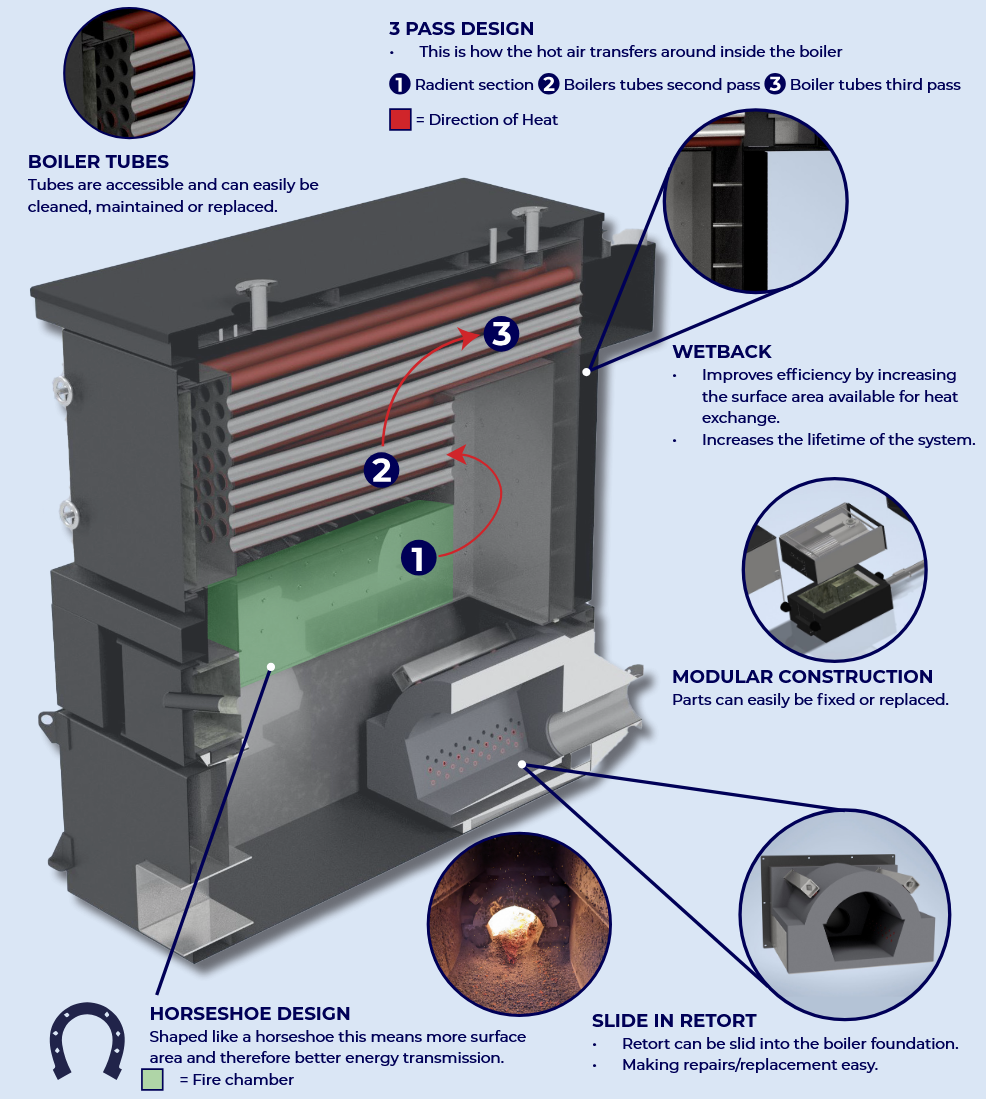

Ranheat biomass boilers begin with a large, water-cooled radiant section—shaped in our signature horseshoe layout. This section absorbs the most intense heat from combustion before flue gases ever reach the convection tubes.

This design:

Reduces thermal shock and expansion stress on tubes

Encourages complete combustion with a long flame path

Lowers flue gas temperature safely, improving heat transfer and emissions

Cheaper systems often send hot gases straight into long, narrow tube banks. It may look efficient—but it leads to uneven wear, ash build-up, and premature failure.

Smaller combustion chambers clog easily with ash and clinker, especially when burning man-made boards, laminates, or fire-retardant MDF. Ranheat fireboxes are:

Spacious and deep, with room for combustion to complete

Lined with refractory to absorb and dissipate heat

Designed to clear clinker and handle variable fuels

Ranheat also offers multiple combustion chamber types, tailored to different waste streams—from chipboard to solid grade laminate. Every firebed is chosen based on your actual fuel, not a generic spec sheet.

Ranheat fire chambers are modular drop-in units, designed to be replaced in a day. There’s no need to dismantle or rebuild your boiler to keep it running.

And we take that principle further:

Pressure vessels, stokers, fans, filters—all modular

Guaranteed access to replacement parts for life

1-year warranty as standard, extendable to 10 years with a service contract

This is how we design for real factories—not just brochures.

Some boiler specs are written to win tenders. We build for endurance.

Ranheat avoids over-long tube banks, using moderate-length exchangers with consistent gas flow and paired shockwave cleaning systems. Combined with wet-back construction and radiant-convective separation, this delivers real-world efficiency—without stress, fouling, or early failure.

Yes, Ranheat boilers can burn pellets. But pellets are expensive—especially in Europe, the UK, India, and North America.

Pellets: 10–15p/kWh, tracking gas prices

Green chip: 4–8p/kWh depending on season and supply

Wood waste from your factory: free or negative cost

Ranheat systems are optimised for using your own fuel—not buying it in.

To meet emissions standards and stay clean under load, we include:

Water-cooled fireboxes to prevent thermal spikes

Optional Flue Gas Recirculation (FGR) to reduce NOx

These features come from design, not bolt-ons.

A Ranheat biomass boiler isn’t built to last five years. Or even twenty. It’s built to run indefinitely—as long as it’s properly maintained.

That means:

Servicing it regularly

Replacing wear parts when required

Letting it do what it was built to do: run

Because every Ranheat system is modular, every component can be changed. You’ll never be told your machine is “too old” or “no longer supported.” We design it to be repaired, not replaced.

So yes—our industrial biomass boilers are more expensive up front. But over a working lifetime, they cost less, deliver more, and keep doing the job year after year. You don’t throw them away. You run them.

And we’re here to support you every step of the way.

📞 Talk to Ranheat about building your system right from the start

✉️ [email protected]

🌐 www.ranheat.com